The Problem

If you have ever made cold brew before, you know it can take up to 24 hours to make a batch of coffee. Being an impatient lot of engineers and designers at New Fundamentals, we thought could you make that process faster while preserving the flavor?

Before we set to work solving our problem, we needed guidance. So, we hit up our friends over at a local Philadelphia coffee roaster to ask them a few questions.

Customer Research

Customer Interviews

We learned from the coffee roaster what their current methods were and what features would be important enough to make them switch to using our machine?

While speed was a consideration, we learned that flavor will always be the top priority. No amount of speed increase will make up for a reduction in beverage quality. Furthermore, there were some other important features the machine had to have:

- Cost – It still has to be relatively affordable for a small cafe operation to buy a unit or two

- Output – Make at least 5 gallons of ready to drink (RTD) per batch or equivalent in concentrate

- Cleanliness – A simple and fast cleaning protocol to use between batches

- Ease of Use – Simple controls and safe operation for baristas

- Speed – 4x or more speed increase compared to their current method

- Differentiation – Could a cafe use it as point of differentiation from their competitors

The Business Case

What we really learned is that the current method of production was cheap and easy. However it was cumbersome to scale, requiring a large amount of space that small businesses don’t often have. So, if our machine is able to brew coffee faster, then we can produce the same amount of coffee in a smaller space. Therefore, increasing the profit per square foot.

Solution Research

We set to work researching how other people have made cold brew in the past. It turns out scientists love coffee, as there were multiple papers published with a myriad of ways to make cold brew.

Ultrasonics

Initially drawn to ultrasonic brewing, we quickly realized it broke one of the above considerations. Cost. A sonotrode large enough to brew 5 gallons of coffee was particularly cost prohibitive.

Vacuum Pressure

We then uncovered a bunch of papers advocating the benefits of brewing coffee using a vacuum. So, we gave that a try and after 20 batches of nasty coffee and a nearly totaled vacuum pump, we realized that vacuum pressure was not the way.

Agitation

One constant in all of the papers was that agitation would increase the extraction rate. Using a magnetic stirring rod in our Vacuum based prototype we were able to validate this claim.

Positive Pressure

Still frustrated with underwhelming coffee, we decided to break with conventional research and try something new. We flipped our vacuum pump around – pressurizing the coffee instead of pulling a vacuum. It worked!

That was the first brew that tasted good, not great, but it tasted like coffee!

Developing a Working Prototype

We decided to move forward with a pressure based extraction system. Although our initial test was at maybe 60% of the quality we needed, we had a plan to refine this method.

Testing

We first established the key variables that contributed to coffee extraction and their impact on the extraction process. Some of them included the following: grind size, pressure, duration, agitation, ambient temperature, water ratio, etc…

We then proceed to brew countless batches of coffee adjusting each of those parameters until we dialed in a configuration that leads to delicious coffee.

Mechanical Engineering

Brewing System

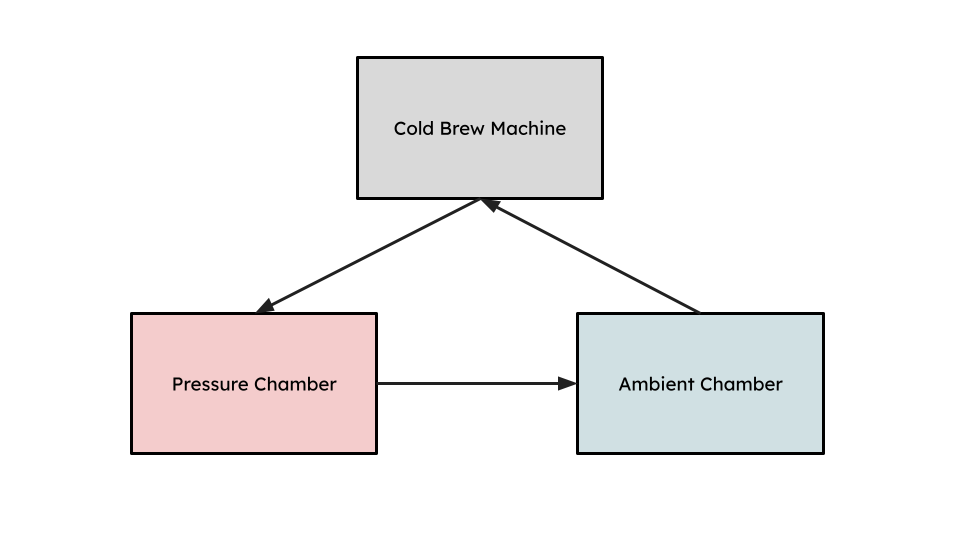

Although we developed a lot of technology to make this machine work, the most interesting aspect of the machine would be the brewing system. We used what we called a “continuous flow pressure system”. This method allowed us to keep the coffee under pressure and circulate the water through the coffee in order to get the benefits of both pressure and agitation.

We use two chambers in order to implement this method of extraction. The first chamber is the pressure chamber which holds the coffee grounds. The second chamber is at ambient pressure and holds the water used for brewing.

The water in the ambient chamber is suctioned up into the coffee brewer and forced into the pressure chamber to generate hydrostatic pressure. However to increase the rate of extraction, we allow a small amount of water to continuously recirculate back into the ambient pressure bucket through the use of calibrated orifice. This allowed the coffee grounds to constantly have fresh water pulling the oils away from their surface.

Other Systems

- Pneumatic Dispensing System – We developed this system to allow the user to quickly dispense all of the coffee they made without straining any hydraulic components.

- Liquid Cooling System – This system was developed to combat any temperature rise that occurs due to friction from the orifice.

- Mechanical Safety Systems – Mechanical fail safes to ensure any malfunction does not lead to bodily harm or a massive mess.

- Cleaning Cycle – A simple method to clean the tubing and flush the system from excess water.

Electrical Engineering

We have always admired things that have a dedicated purpose. Without having to consider a million and one features, those machines are able to really excel in one or two tasks.

We wanted our machine to carry that same ethos. So we forwent the standard computer control system and opted for an analog control system. This makes for very simple operation for baristas and a very tactile experience that feels almost luxurious in an era of unsatisfying screen based user interfaces.

Human Centered Design

Designing for Humans

Given the potential hazards of working with pressure, we wanted to make it both intuitive and “idiot proof”. Even if you have never been trained on the machine you should be able to safely operate it and make excellent coffee.

To prevent setup errors, we designed a system with alternating male and female connectors, making it impossible to incorrectly configure the lines. Furthermore, we designed the circuitry to have 3 distinct states: standby, brewing, and dispensing. Using a 3 way toggle, we prevent users from activating the brewing and dispensing system simultaneously.

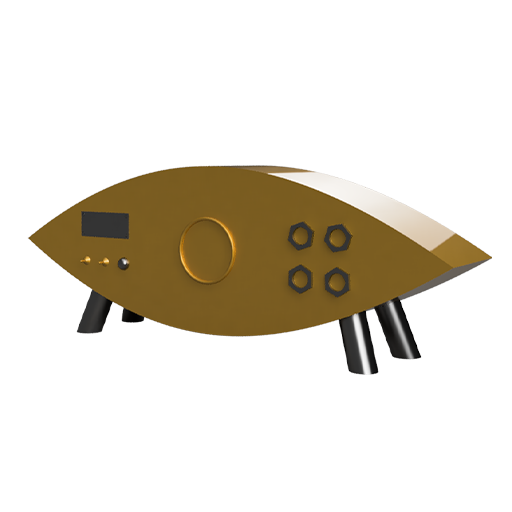

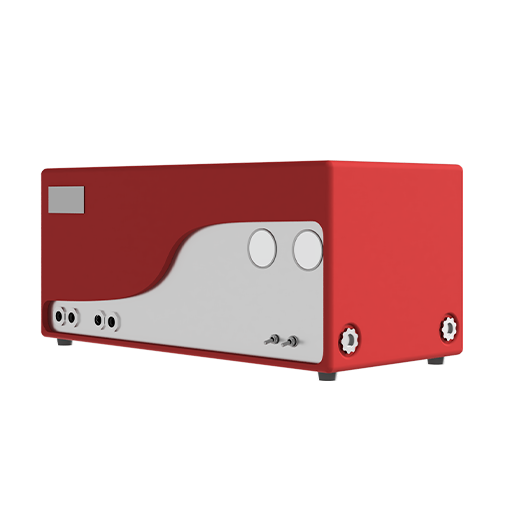

A Case for Beauty

Through our conversations with cafes, we realized that our machine isn’t just a tool – it also has the potential to shape the atmosphere, much like an espresso machine. We wanted to design an enclosure that makes a statement, and contributes to the identity and experience of the cafe

We drew inspiration from vintage guitar amps, crafting an enclosure with a tweed fabric covering over wood. To ensure it meets NSF standards for food safety, we applied an epoxy resin seal, making it both durable and compliant.

We settled on a red tweed with a polished stainless steel faceplate.

Results

This project is still a work in progress! The mechanical systems work flawlessly and the flavor of the coffee is out of this world. In blind taste tests trained coffee professionals were unable to tell the difference between our coffee and that brewed by our roasting partner.

However we still have to put the finishing touches on the enclosure and do some final tweaks before the coffee maker is ready to go to market.