The Problem

The traditional mens wallet is a large hunk of leather that consumes an immense amount of pocket space. If placed in your back pocket, some wallets are so thick that they can cause back pain. We wanted to change that.

We wanted a wallet that could hold all of the contents of our standard wallet, while leaving room in your pocket for other things like keys, chapstick, pocket knife, etc…

Product Research

Compact wallets are not anything new; Ridge, Bellroy, and Mighty Wallet quickly come to mind. However all of these compact wallets suffer from various issues that prevent them from being the ideal solution.

- Ridge: It is made of machined aluminum which makes it an inflexible and awkward lump in your pocket. Furthermore, they use elastic to secure cash which is prone to wearing out over time.

- Bellroy: These wallets are significantly thinner than traditional wallets, but they continue to use the bifold design that adds significant bulk when folded.

- Mighty Wallet: Using Tyvek, these wallets are as thin as they can get. However, they do not stitch their wallets, rather relying on an origami based folding pattern. The origami design easily unravels, spilling the content of the wallet.

Prototype Design

First Principles Thinking

Using first principles thinking we thought about what we are trying to carry, then built the wallet around that.

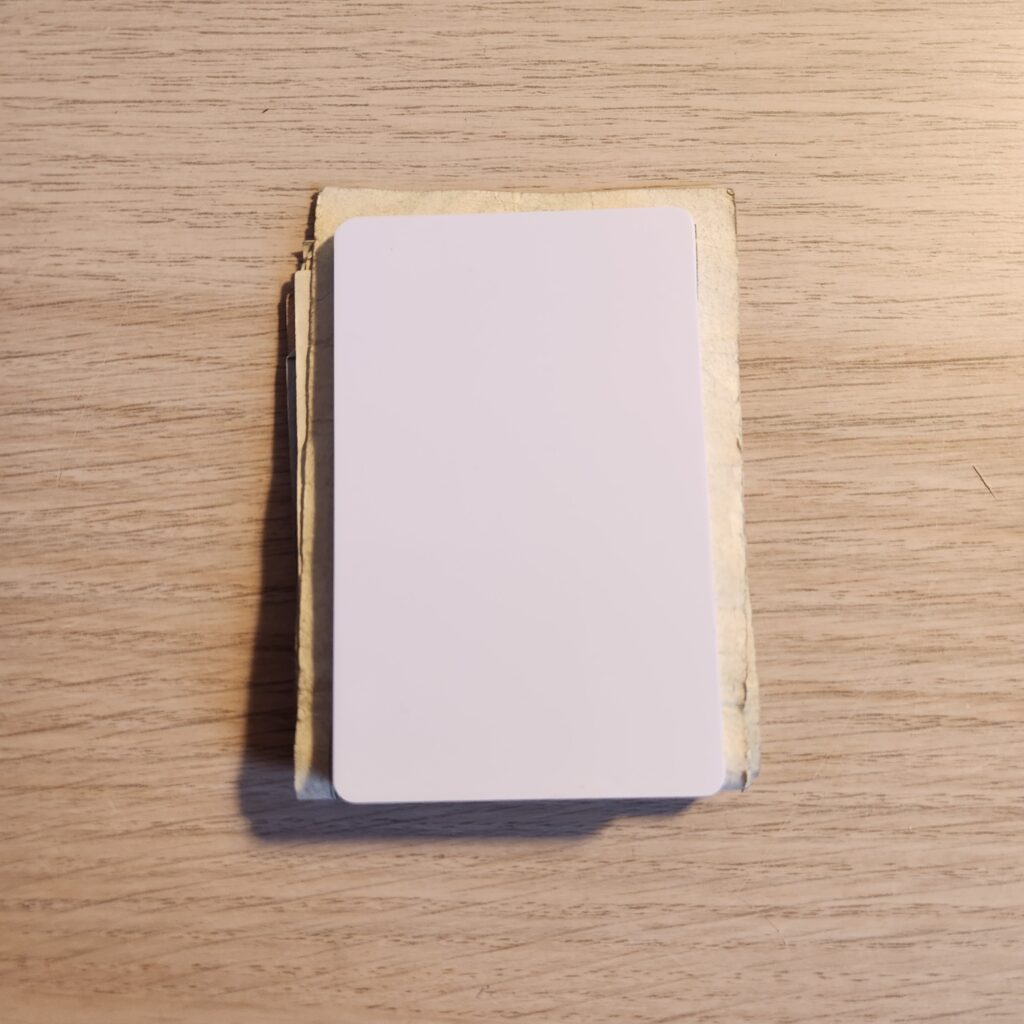

We decided we wanted to hold up to 8 cards and 20 bills. The cards had to be especially easy to access, as from our observations, we realized they are used significantly more often than the cash.

We started by playing with cash and cards and determining what would be the most compact way to stack them together. We realized that folding the cards positioned vertically and cash folded lead to the most pleasing combination of thickness, size, and accessibility.

Materials Selection

Although leather has been the default material for wallets for years, we felt that it wasn’t the best material for our wallet. Leather has a few key failings.

- Water Absorption: Although somewhat water resistant, once leather becomes saturated with weather, it is very slow to dry out. Furthermore, water prematurely ages the surface finish and reduces it’s overall lifespan

- Thickness: Leather loses strength the thinner you make it. So to make it as thin as we would like, it would tear very easily.

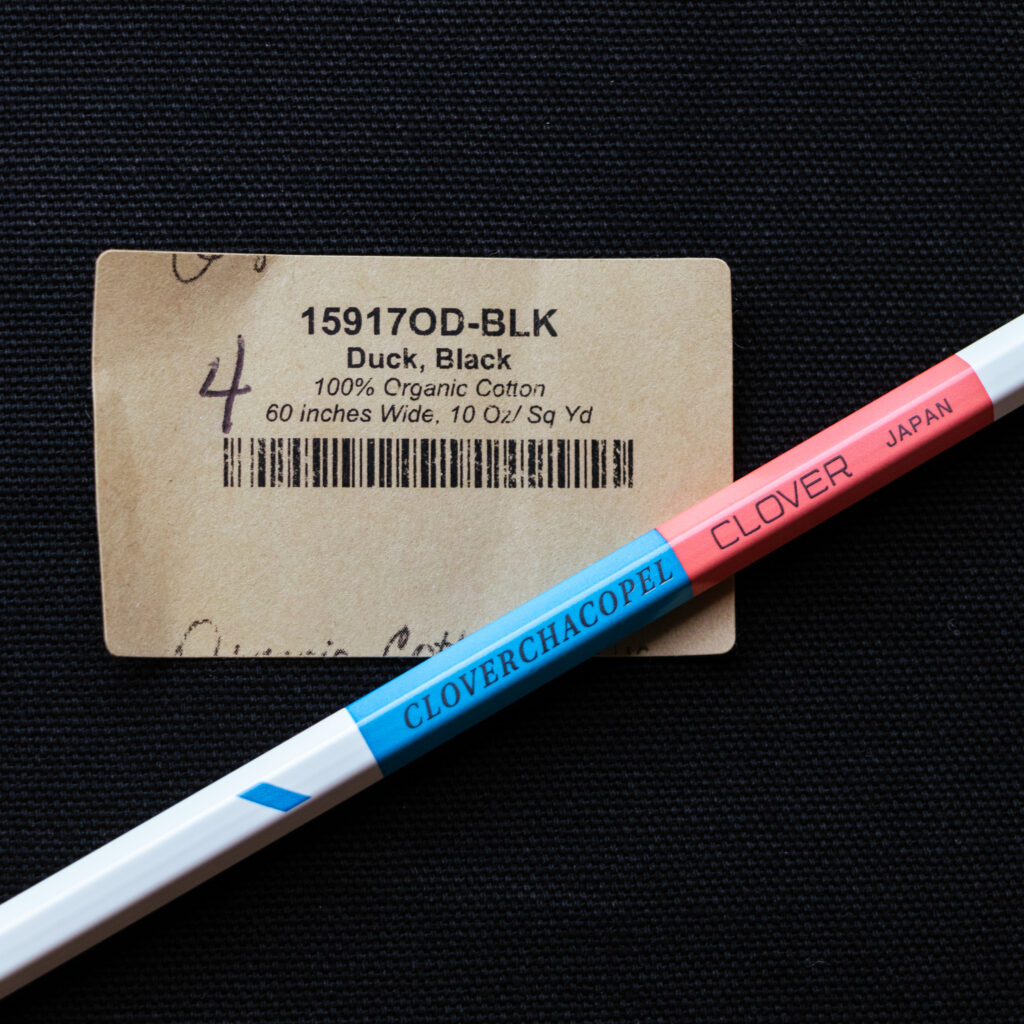

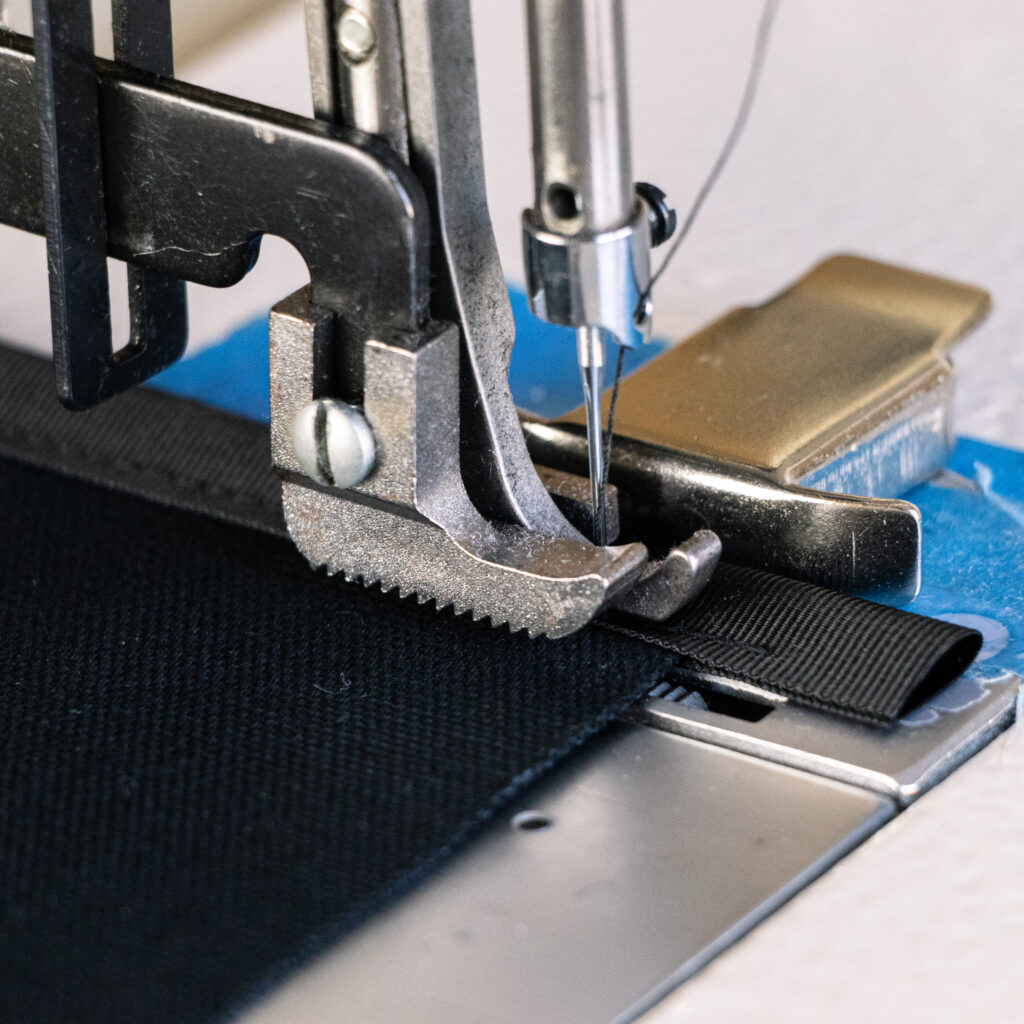

After testing multiple materials like rip-stop nylon, vinyl, sail cloth, and various fabrics. We settled on a heavy 10oz canvas and nylon bias tape. These two fabrics had the best hand feel, natural stretch, and durability. It also does not get damaged if wet and is extremely hard wearing. If it is good enough for a Carhartt work jacket, it is good enough for a wallet.

Soft Goods Pattern Design

Taking what we learned in our first principles thinking exercise and our newly selected materials. We set about drafting the pattern. We focused first and foremost on size. We wanted this to be the most compact wallet possible.

However we had a hiccup. Our first few prototypes had an issue with the cards falling out of the wallet when turned upside down. It turns out that exposing too much of the cards did not create enough friction to keep the cards in their position.

So, we raised the lip of the outer pockets and adjusted the pattern to create a more secure fit for the cards.

The Results

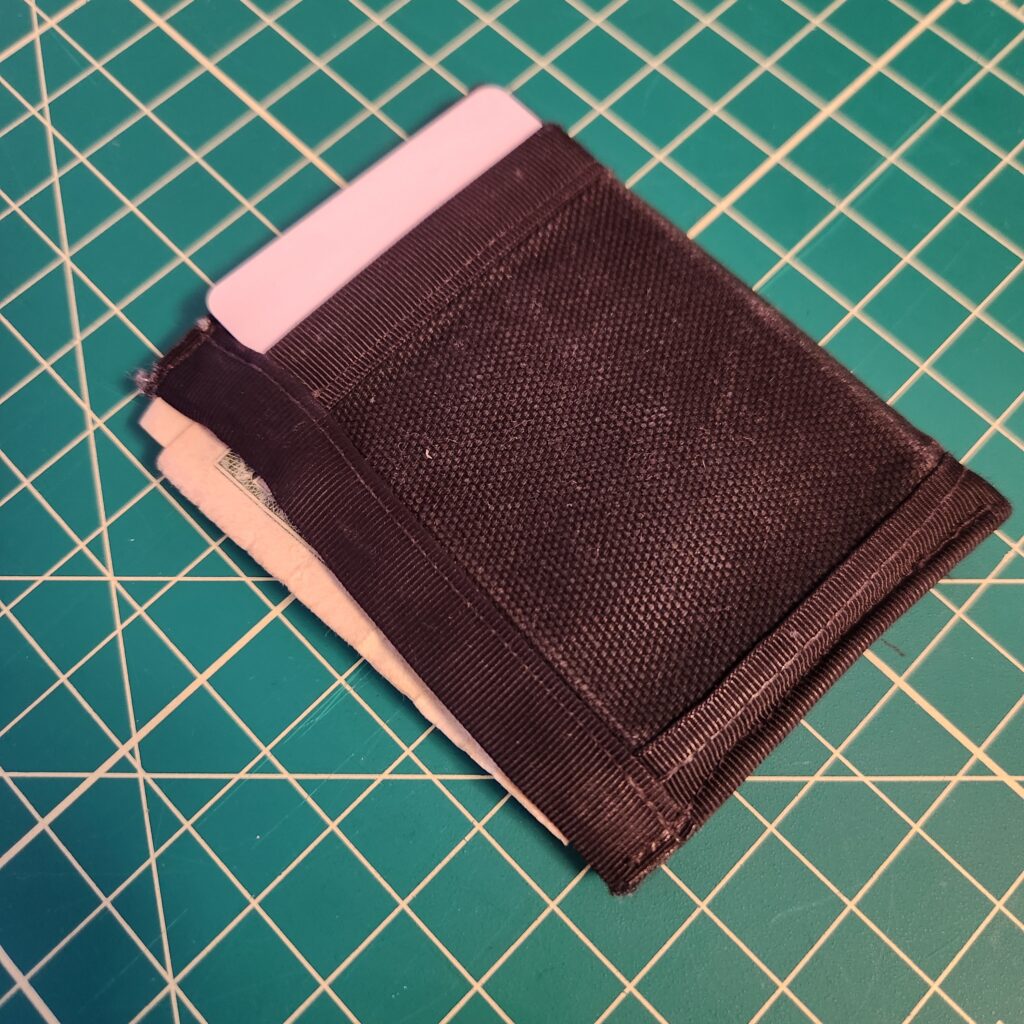

The final result is the Micro wallet as you see it today! It is a hard wearing wallet that has served us well for years. It has caught on locally with cyclists in our area, as it fits nicely in their back jersey pockets.

Here is my personal wallet, that has been through hell and back for over 5 years. It is still going strong!